FAQs

Everything you need to know about our service. Can’t find the answer you’re looking for? Please, chat to our friendly team.

Experience precision with our non-destructive testing. Comprehensive analysis & reports for safe, reliable structures.

In modern times, it is crucial to ensure materials and parts are safe and of good quality. The solution lies in adopting a practical inspection and reporting system. Because of its innovative yet non-invasive approach, non-destructive Testing (NDT) has emerged as a frontrunner.

NDT is a leading inspection/testing method that values thorough evaluation while maintaining the quality and usefulness of materials and components. Its beauty lies in its simplicity – the ability to inspect, report, and evaluate without causing a scratch.

NDT isn't a one-size-fits-all approach. Instead, it's a vast domain filled with specialized techniques that cater to diverse applications:

- Magnetic Field Testing:This fascinating method employs magnetic fields to probe defects in ferromagnetic materials. Even a tiny change in the magnetic field can indicate a possible problem, prompting inspectors to investigate further.

- Gamma rays and radiographic testing use gamma rays to show flaws in materials through visual representation. Detectors capture rays passing through the subject, flagging variations and revealing the material's internal structure.

- Acoustic Emission Testing: Listen closely for materials to speak. This technique captures the acoustic signals emitted when a material experiences stress. It's akin to a doctor's stethoscope but for materials, helping pinpoint areas on the brink of structural failure.

- Visual testing is a vital part of NDT. It uses cameras, drones, and magnifying tools to find surface irregularities. In an era of digital augmentation, tools like 3D imaging and infrared thermography are elevating the capabilities of this method.

- Ultrasonic Testing: A technique that echoes the principles of sonar, it employs high-frequency sound waves to explore materials in-depth. As these waves interact with the material, their reflection or transmission offers insights into hidden defects or variations.

- Dye Penetrant and Liquid Penetrant Testing: Think of this as the detective of NDT. This method uses coloured or fluorescent liquid on a material's surface. It helps reveal defects that may not be visible to the naked eye.

To fully appreciate the advantages of NDT, one must understand its counterpart – destructive testing. While the latter tests materials to their breaking point to understand their maximum potential, NDT adopts a gentle approach. Destructive tests are essential for deducing a material's endurance limit, but NDT is indispensable for periodic checks, especially in crucial sectors.

Welding is more than just fusing materials. It's an art and science combined, especially evident in industries like aerospace, shipbuilding, and construction. Ensuring the integrity of welds is paramount. We can guarantee that these crucial joints endure the harshest conditions through NDT, particularly visual inspections and radiographic testing.

Pressure vessels, a mainstay in several industrial processes, operate under unique conditions. These containers, whether part of a massive industrial complex or an intricate part of machinery, must be faultless. Leak testing, an NDT subset, ensures they are free from defects that could compromise their function or safety.

In a rapidly evolving industrial landscape, NDT is not just keeping pace but often leading the charge. The reliance on NDT grows as we delve deeper into sectors like renewable energy, space exploration, and advanced construction. It's not just about ensuring safety anymore; it's about guaranteeing optimal performance, longevity, and efficiency. Furthermore, with AI and machine learning integration, future NDT techniques promise even greater accuracy and efficiency.

Sectors continue to expand their limits, emphasizing the significance of safety and quality inspections such as NDT. It merges human proficiency, technological progress, and the steadfast commitment to maintaining material soundness. Recognizing and adopting NDT is the progressive path for all parties involved, from producers to end-users.

In a constantly changing world, it's essential to ensure our creations last, work well, and stay safe. We should prioritize and invest in making our creations last, work well, and stay safe.

It's not just a want. We need to prioritize and invest in NDT, also known as Non-Destructive Testing. This is because NDT plays a crucial role in ensuring the durability and dependability of our creations.

NDT uses techniques like ultrasonic, radiographic, and magnetic particle testing to find flaws and defects in materials without causing harm. This not only saves time and resources but also ensures the safety of both workers and end-users.

NDT gives us confidence to push boundaries and explore new possibilities in fast-paced industries that require innovation. By conducting thorough inspections and quality checks, we can identify potential issues before they escalate into costly and dangerous problems. This proactive approach not only saves money but also prevents accidents and ensures the reputation of our products and brands.

Furthermore, a specific industry or sector does not limit NDT. From aerospace and automotive to construction and manufacturing, NDT is applicable across various fields. It helps us check buildings, find problems in pipelines, and make sure machines work well. By embracing NDT, we can enhance the overall quality and performance of our products, leading to increased customer satisfaction and loyalty.

Investing in NDT is not just a wise decision; it is a necessity. By investing in training, equipment, and inspections, we can stay ahead and be competitive in the market. The benefits of NDT go beyond immediate cost savings; they extend to the long-term sustainability and success of our businesses.

NDT connects human expertise with technology, ensuring safety, quality, and durability of our creations. It's a tool that gives us confidence in our products lasting over time, helping us embrace the future. By focusing on and investing in NDT, we can create a safer, more reliable, and prosperous future for everyone involved.

By choosing SAS Projects, you can trust our team to provide the expertise and support you need to ensure your building is safe and compliant.

Reach out to us to discuss your high-rise building's needs and challenges.

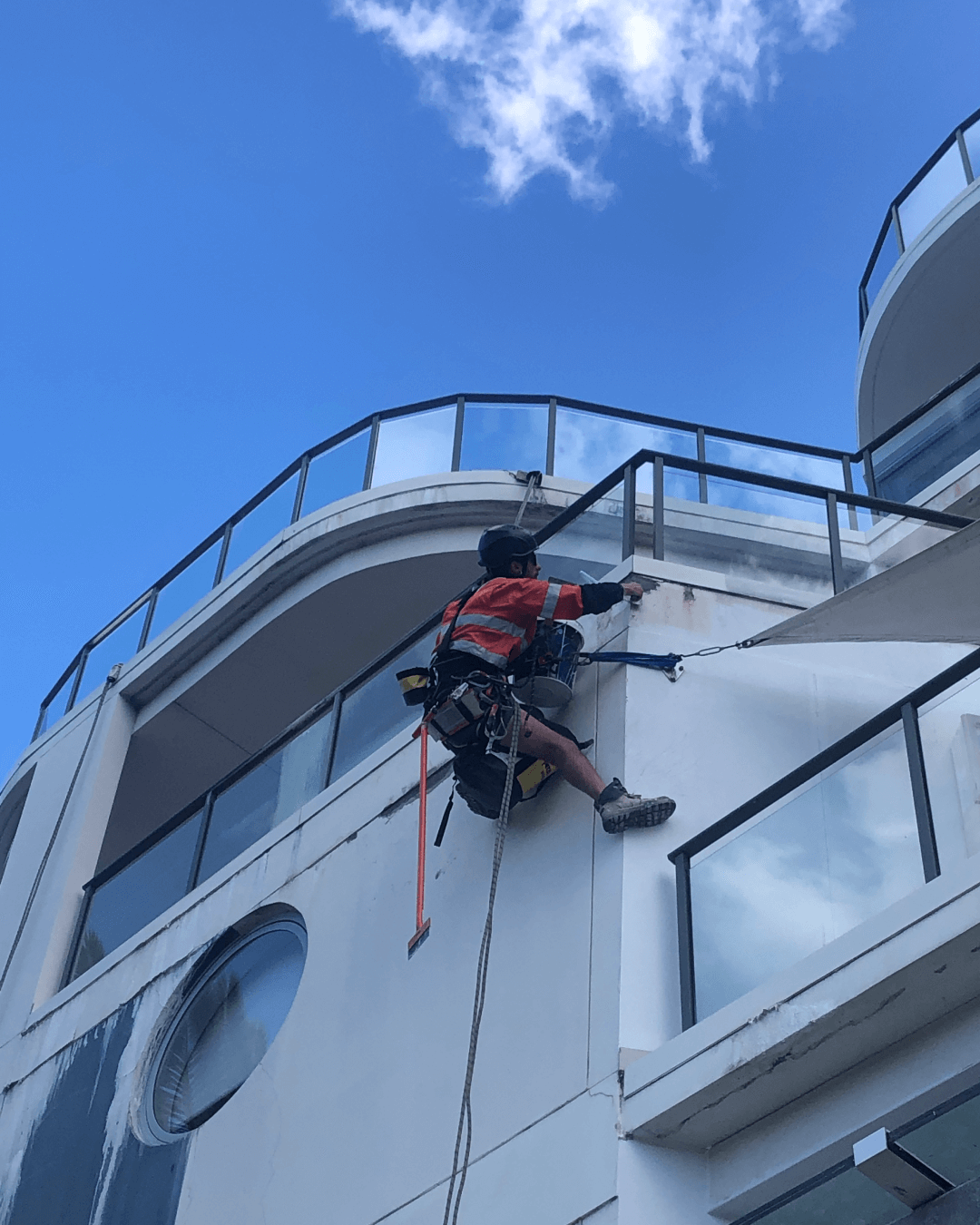

We'll develop a tailored plan to address your building's requirements, providing expert rope access solutions.

Experience the difference our comprehensive rope access services make in enhancing your property's value and appeal.

Everything you need to know about our service. Can’t find the answer you’re looking for? Please, chat to our friendly team.

NDT is a range of testing techniques used to evaluate the properties of a material, component, or system without causing damage, with results documented in detailed reports.

NDT maintains the object's usability post-testing, eliminating potential waste. It's cost-effective, safe, and provides immediate insights without destructive consequences.

Industries like aerospace, automotive, oil & gas, construction, and power generation rely on NDT for assessing reliability, safety, and product integrity.

When conducted by certified professionals, NDT provides highly reliable results, making it a trusted method for critical inspections in various industries.

Popular NDT methods include ultrasonic testing, magnetic particle testing, radiographic testing, dye penetrant inspection, and visual inspection.

The depth of the NDT report varies based on the client's requirements. Typically, it includes findings, analysis, images or graphs, and recommendations for any required action.