FAQs

Everything you need to know about our service. Can’t find the answer you’re looking for? Please, chat to our friendly team.

Offering advanced engineering assessments combined with NDT for integrity without compromise.

In the dynamic engineering world, ensuring the safety and reliability of structures and materials remains paramount. This mission's heart is the crucial combination of engineering assessment and report backed by non-destructive testing (NDT). This convergence is a testament to the advancements in engineering and technology, promising a future of safer, more resilient infrastructures.

An engineering assessment is a detailed evaluation conducted by experts. We examine the condition and strength of various structures, such as bridges, buildings, aircraft, and pressure vessels. Aided by multiple testing methods, this assessment identifies potential structural defects, ensuring timely interventions.

Non-destructive testing (NDT) is a collection of techniques used in engineering. We use these techniques to evaluate materials, components, or systems. The main advantage of NDT is that it does not cause any damage during the assessment process. In a way, NDT methods are the silent sentinels, ensuring that our infrastructures stand the test of time.

Visual Inspection: The initial visual inspection defence uses the naked eye or advanced optical systems to find surface defects. Armed with keen observation skills, a building inspector can detect issues that might escape an untrained observer.

Magnetic Field Testing: Deploying a magnetic field, this technique assesses defects in ferromagnetic materials. Distortions in this field often hint at potential anomalies within the material.

Eddy Current Testing: This vital NDT technique uses fluctuating magnetic fields to inspect non-ferromagnetic materials. A disruption in the eddy current typically suggests a defect.

Radiographic testing employs gamma rays to visualize the interior of materials and detect imperfections that are not visible to the naked eye.

Phased Array and UT use sound waves to find material defects or imperfections. Variations in wave reflections or transmissions indicate potential issues.

Remote Field Testing: Predominantly used in pipelines and tubular products, this method is invaluable in industries reliant on fluid dynamics.

While machines and methods are essential, the human element remains irreplaceable. Hiring experts like structural engineers and building inspectors is crucial for thorough assessments. They have deep knowledge of mechanics and can quickly spot hidden structural issues.

Supported by organizations like Engineers Australia, these experts have technical knowledge and the duty to keep the public safe.

Pressure vessels, often found in industries ranging from energy to chemicals, operate under intense conditions. NDT techniques, such as UT and radiographic testing, are essential due to the risks and pressures involved.

Building inspections using NDT in civil engineering ensure the safety of structures such as skyscrapers and homes. These inspections detect hidden problems and protect us from potential dangers.

NDT experts play a crucial role in ensuring the integrity and safety of various structures. Their expertise is critical for identifying potential safety threats, whether inspecting pressure vessels or conducting building inspections. Experts in mechanics can find hidden structural issues that are not obvious to the naked eye.

NDT experts, supported by reputable organizations like Engineers Australia, have the necessary technical knowledge and skills to perform their duties effectively. They learn different non-destructive testing methods like ultrasonic and radiographic testing. These methods are essential for checking the condition of pressure vessels and other vital parts.

Pressure vessels, commonly found in industries like energy and chemicals, operate under extreme conditions. The risks and pressures involved make it imperative to employ NDT techniques to ensure their reliability and prevent catastrophic failures. Inspectors need help in vessels to protect workers and the environment.

In civil engineering, NDT is vital in ensuring the safety of structures like skyscrapers and homes. We conduct building inspections using NDT techniques to identify any hidden problems within the system. These inspections find hidden problems like rust, cracks, or bad welds that could cause buildings to collapse. Experts use special techniques to see what the eye can't.

By identifying these hidden problems early on, NDT experts help prevent accidents and protect the public from potential dangers. Their expertise allows them to assess the structural health of buildings, ensuring that they meet the necessary safety standards and regulations. This provides peace of mind to occupants and contributes to the structures' general resilience and durability. Contribution to the available strength and durability of the building structure.

Their expertise in mechanics, backed by groups like Engineers Australia, helps them find hidden structural problems and avoid potential disasters.

NDT is necessary for checking the safety of structures like pressure vessels and skyscrapers. It helps protect the public and reduce risks. We use inspection reports to understand the results of NDT.

Every engineering assessment culminates in a detailed inspection report. This pivotal document details findings, offering insights, pinpointing potential risks, and suggesting corrective measures. For stakeholders, this report is more than just a document; it's a roadmap to ensuring infrastructural integrity.

As our engineering accomplishments increase in size and intricacy, the tenets of engineering evaluation and documentation, supplemented by non-destructive examination, become increasingly vital. Experts, such as engineers and inspectors, guarantee the safety and robustness of our structures. Engineers Australia supports them, and they are devoted to thoroughness and commitment.

By choosing SAS Projects, you can trust our team to provide the expertise and support you need to ensure your building is safe and compliant.

Reach out to us to discuss your high-rise building's needs and challenges.

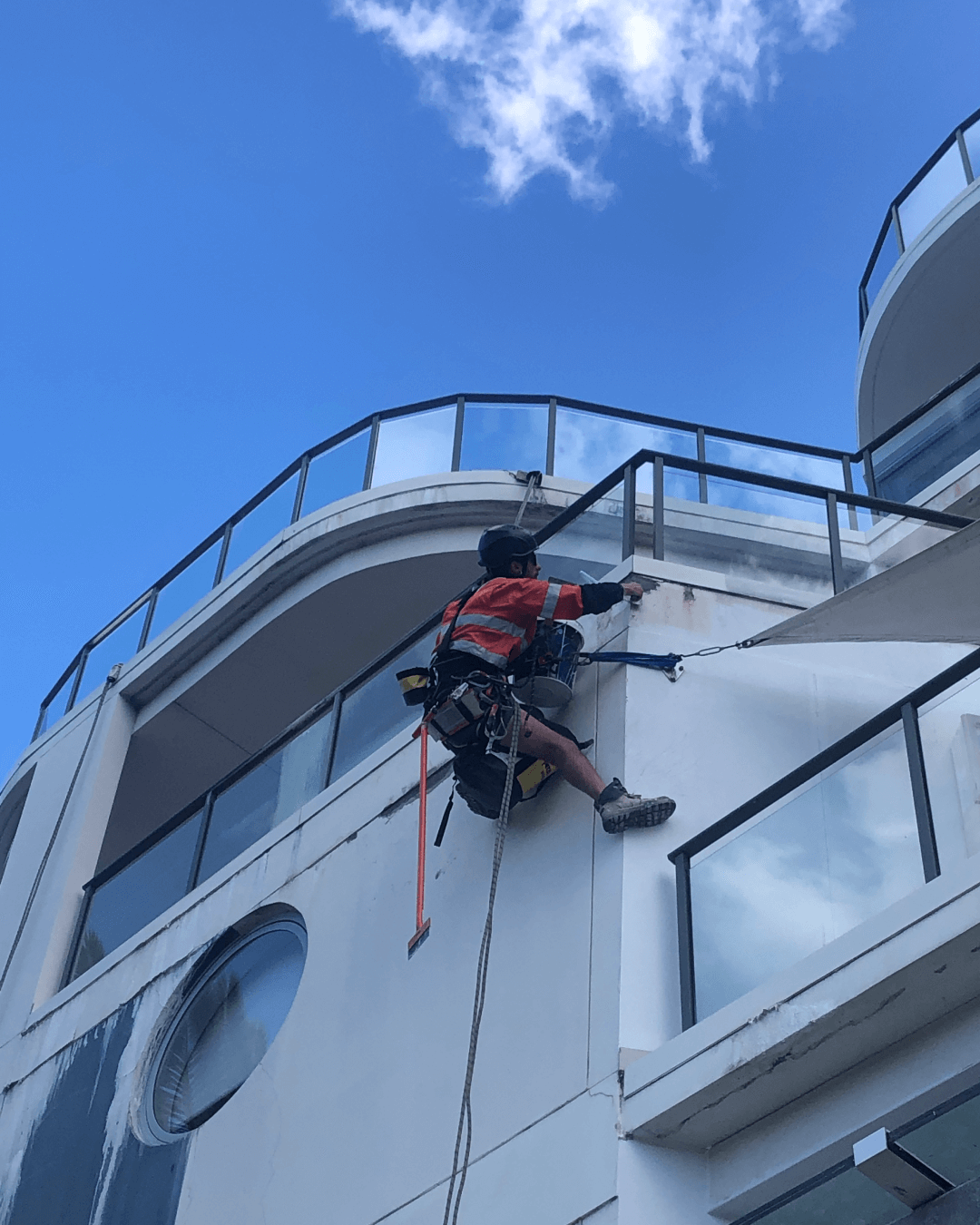

We'll develop a tailored plan to address your building's requirements, providing expert rope access solutions.

Experience the difference our comprehensive rope access services make in enhancing your property's value and appeal.

Everything you need to know about our service. Can’t find the answer you’re looking for? Please, chat to our friendly team.

In engineering assessments, NDT offers a way to evaluate material properties, structural integrity, and defects without causing damage or altering the structure.

Combining the two provides a holistic view of a structure's health, safety, and durability, ensuring comprehensive analysis without compromise to the material.

Not always. While many modern engineering assessments incorporate NDT for its advantages, the approach depends on project needs and specific circumstances.

Industries such as construction, aerospace, transportation, and energy can significantly benefit from this approach, ensuring safety, compliance, and longevity.

NDT results offer tangible data on potential defects or weaknesses. This data enriches the engineering assessment report, providing actionable insights and recommendations.

Yes, different challenges might require specific NDT methods. For instance, ultrasonic testing might be preferred for detecting internal flaws, while magnetic particle testing might be used for surface defects.